If you haven't read anything of mine on measuring intake restriction, you'll want to read this series first before you read this.

A subscriber, John Marlow, recently submitted a question that I thought I'd take a few moments this week to talk about. I also saw a similar question out on one of the forums that had linked to an article here so I figured it was worth talking about.

"Why not just measure intake restriction using an OBDII tool to read MAF (Mass Air Flow Sensor) values (on cars equipped with a MAF) and determine if flow is better that way?" -- John Marlow, Topeka, KS

Thanks John for your question!

This is actually really good thinking and using the MAF to see if a modification helped or not would be better than the "butt dyno", but I still lean on the differential pressure meter for some reasons I'll discuss in this article.

As long time readers know, I like to use a differential pressure meter (or vacuum gauge, or digital manometer) to measure restriction in the intake system to guide modifications to that system. I like to use this rather than the MAF sensor because with a differential pressure meter, I can take measurements at different points in the system while the MAF only allows an overall figure. If I want to know if a particular bend is restrictive or if the resonator box is causing the problem, I can use the DPM (differential pressure meter) to measure the pressure drop across those parts individually and figure out which is the culprit of my flow loss.

The MAF measures a few different things while differential pressure only measures pressure drop which makes MAF readings less repeatable which is important for "scientific" modification. MAF readings are also much harder to measure on a OBDI (pre-1996) car.

So let's unpack some of these points a little bit to make more sense of them.

The MAF (Mass Air Flow Sensor) literally measures how much air is flowing through the intake system and into the engine. It measures the MASS of the air, not the volume. The volume of air going into the engine is almost always the same, its mass (or how much actual air is in that space) changes with air temperature, pressure and humidity.

On the surface that seems like a great way to compare two different intake setups.

However, the mass air flow sensor measures the total amount of air by sensing the amount of air, velocity, temperature and even humidity all at one time. In other words, the MAF is a very good indicator of exactly how much air flow is going through the pipe. However, in different locations at different times, the exact same intake system would produce different values. Changing other engine components downstream (in the engine, header, etc) could also alter MAF readings somewhat.

Two sets of back to back readings from a MAF generally follow a similar line and you could try to average the data plots and use a best-fit line and all of that to compare two MAF graphs, but it's an enormous pain and it may still give deceptive results, especially with the relatively small changes in air flow that intake mods yield.

Just because one intake gives you better MAF values on a few runs doesn't necessarily mean it's better - unless they MAF values are drastically different and the tests were done as closely together as possible.

"Geeky" Project Idea

You could possibly use a MAF under lab conditions as a very inexpensive "flow bench." I may build one at a later date if I have the parts laying around. If you can control temperature, conditions and atmospheric pressure of the air flowing through the MAF, it'd be an awesome way to measure flow for really cheap given a 12v power supply and the right fixtures. I know a few small but VERY successful Formula teams that use a "flow bench" using a differential pressure meter on their cylinder heads and so on. They use a heavy duty shop vac, a custom built plenum then mount the cylinder head to a seal on the top of the plenum. They use the differential pressure meter to see how much pressure drop they have at different valve lifts. Very slick.

The MAF only allows us to see the birds eye view of air flow. In other words, we can't use the MAF to figure out where in the factory intake system the restriction is hanging out. The power of using a differential pressure meter correctly is that you can actually locate exactly what's causing the restriction. Using the MAF method, you could only make random modifications and see if they worked. Using the DPM method you can make targeted changes which saves time (and probably money).

The Ferrari Enzo has no "creature comforts", but still uses enclosed air boxes..NOT exposed conic air filters.

In my experience, modified factory systems generally produce better results than aftermarket systems that completely scrap the box. They are certainly cheaper, quieter, cleaner (both visually and in terms of engine wear), and in almost all cases they out perform the aftermarket system when done correctly - in the real world, not always on the dyno. If you listened to the TU Premium Interview with John Grudynski, the fastest car isn't necessarily the most powerful, it's the one with the power AND good transient response which the second is where boxed systems shine and why I suspect you'll never see even the most hardcore Ferrari or Lamborghini with an exposed air filter like most aftermarket systems.

I use the differential pressure method because it allows me to get repeatable results on which places in the system are "clogging up the pipes."

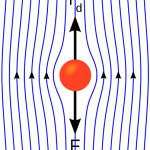

Differential pressure, rather than MAF readings, measure what's known as pressure drop. Pressure drop has nothing to do with the actual amount of air flow, per se. It's related but that's not what it's measuring. Instead, for our purposes anyway, it's simply a measurement of restriction. Pressure drop is caused anytime there is a restriction to flow whether that be a sharp bend, an obstruction, excessively rough surface, excessive length or a really crazy phenomenon known as turbulent flow.

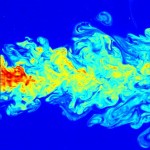

There are two types of air flow, Laminar flow and Turbulent flow. Laminar flow is very predictable flow and most air flows this way. Turbulent flow is an area of deep research and there is actually a very significant prize available in the academic world (I believe $1M) for anyone who can even give a somewhat decent theory of turbulent flow that can be used to model flow in these situations. Turbulent flow is how air behaves when it's moving really, really fast.

When air becomes turbulent there is typically a lot of pressure drop that can be seen according to my favorite physicist. Therefore, differential pressure readings can account for or even expose turbulent flow should it become and issue.

Pressure drop is an indication that air flow is going down but it's not a direct measurement of air flow.It's also a very sensitive measurement if you're using a small unit like inches or centimeters of water.

Obviously, measuring MAF voltages on an OBDI car can be done, but you need expensive equipment to do that accurately and so on older cars, the MAF reading thing is completely out.

Finally, while measuring a MAF reading on an OBDII car is easy with an OBDII reader with datalogging capabilities, the results require much more analysis and care to be useful.

In short, I still recommend the differential pressure meter as a tool in your tool box. It is universally applicable so you can use this "modding tool" on any vehicle and in addition to measuring intake restriction it can be used for measuring aerodynamic pressures and determining the best place to put intake ducts and cooling vents for brakes, passengers, etc.

Extremely Limited Time Offer - 3 Days Only

Get a MASTERS DEGREE in Performance Tuning from the BEST in the Field for ONE low package price

For 3 days only, get ALL of our PREMIUM (not available anywhere else) Tuner University Courses featuring some of the greatest minds in motorsports:

- Top 10 Performance Myths Class (MP3 and Edited Transcript) - $29.95 value

- Performance on a Sip of Fuel Class (MP3 and class manual) - $69.95 value

- Header Design Secrets with John Grudynski (MP3 and transcript) - $69.95 value

- Dirty Secrets of Oil with Ryan Stark (MP3 and transcript) - $69.95 value

- Engine Tuning Secrets with Ben Strader of EFI University (MP3 and Transcript) - $69.95 value

Get all of the above courses (many of which not currently available anywhere else) for one single price of just $309.75 $69.95. A HUGE package savings.

You can also buy any of these individually through our resource center, but I don't know why you would as this is basically the whole store for the price of just 1 course. You'll get the MP3 recordings of each class as well as a transcript or companion manual with each course and you'll be able to download them all INSTANTLY.